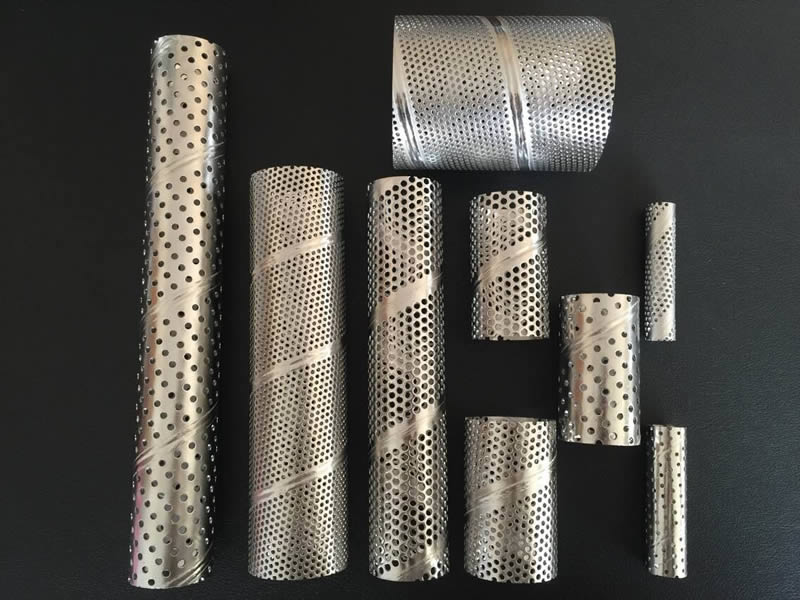

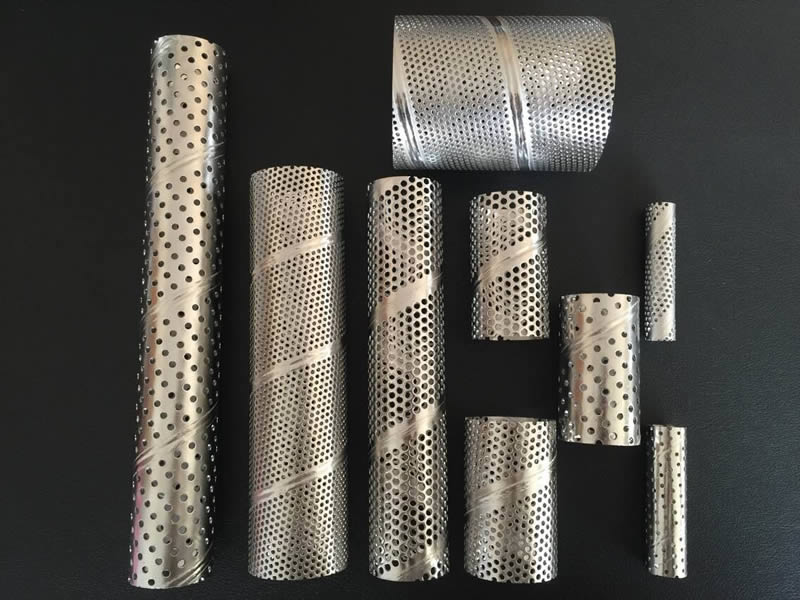

Perforated tubes, with their durable construction and flexible hole designs, are perfectly suited for high-pressure filtration and separation processes. Essential in sectors like automotive, petrochemical, and water treatment, these tubes deliver enduring durability and are designed to withstand wear and corrosion, ensuring reliable performance across various applications.

Perforated Tubes

Specifications

Diameter Range

- Small Diameter Tubes: Available in diameters of 10mm, 15mm, and 20mm. These sizes are suited for precise applications such as medical devices, small-scale filtration systems, and detailed architectural elements.

- Medium Diameter Tubes: Comprising diameters of 25mm, 30mm, and 35mm. These mid-sized tubes are versatile, ideal for moderate filtration needs, automotive components, and decorative uses in construction.

- Large Diameter Tube: Offering a diameter of 500mm. This size is tailored for extensive applications including industrial filtration, large architectural projects, and infrastructure development, providing substantial coverage and capacity.

Length Options

- Short Lengths: Consist of lengths such as 50mm, 100mm, and 200mm. Perfect for compact projects or when smaller segments of tubing are required for specific functionalities.

- Standard Lengths: Including lengths of 500mm and 1200mm. These are commonly used in a variety of industrial, commercial, and architectural applications where standard size tubes can be efficiently utilized.

- Custom Lengths: Catering to unique project requirements, lengths can be customized beyond the standard options to meet specific design or application needs.

Margin Specifications

- Length Margins: A standard minimum margin of 20mm along the tube’s length ensures stability and facilitates handling during installation or integration into larger systems.

- Width Margins: The width margin can start from 0mm, maximizing the perforated area of the tube. Width margins are adjustable based on client specifications to align with project requirements, offering flexibility in design and application.

Situated in Anping County, the nucleus of the wire mesh industry, our company stands as a testament to the seamless integration of traditional craftsmanship and contemporary innovation. As both a manufacturer and exporter, we offer a wide array of wire mesh products with diverse specifications and incorporate advanced technological solutions, serving the global market. Our portfolio exemplifies outstanding quality across a broad spectrum of wire mesh products. We are committed to providing optimal solutions for various applications, including industry, decoration, and filtration, among others. Our journey is marked by a steadfast dedication to research and development, ensuring the continuous introduction of versatile product lines designed to meet the complex needs of our clients worldwide.

Our approach to manufacturing combines advanced technology with refined techniques, ensuring each product is crafted to meet the highest industry standards.