DESCRIPTION

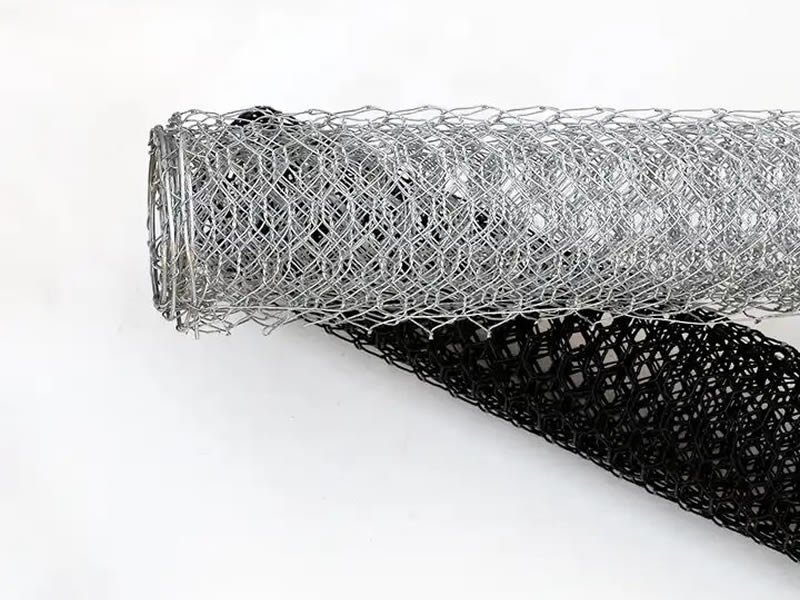

Hexagonal wire netting, also known as chicken wire, is crafted through a specific weaving process that yields its characteristic hexagonal pattern. Available in various dimensions, it caters to an array of applications ranging from poultry enclosures and garden fencing to stucco netting in construction and erosion control projects.

Material

- Galvanized Steel: Coated with zinc to prevent rust, ideal for outdoor use.

- PVC-Coated Steel: Steel wire covered with PVC for extra durability and available in different colors, suitable for decorative purposes.

- Stainless Steel: Highly resistant to corrosion and rust, perfect for harsh environments and offers a long lifespan.

Weaving

- Weaving Machine: The machine pulls wire from spools and uses rotating parts to bend the wire into hexagonal shapes.

- Twisting Method: Wires are twisted together at intervals to secure the hexagonal shapes and add strength to the netting.

- Reverse Twisting: In some cases, the twists alternate directions to make the netting more durable and prevent it from unraveling.

Barbed Wire

Stainless Steel Wire

Anping Boteng Wire Mesh Co., Ltd. specializes in the manufacturing and export of wire mesh products and plastic mesh netting products, with a history spanning over 20 years. Our product range encompasses stainless steel mesh series, welded wire mesh series, iron steel wire, wire mesh fences, fence posts, wire nails, plastic mesh, expanded steel mesh, wire mesh processing products, and various filter elements. We are capable of producing and supplying products in various specifications, tailored to meet our customers’ requirements, and we offer customization to suit their needs.

Boteng Wire Mesh Product Catalog and Overview

Anping Boteng Wire Mesh Co., Ltd. specializes in manufacturing and selling wire mesh and plastic mesh products. With over 20 years of expertise, we collaborate closely with our partners to deliver high-quality metal wire mesh. Skilled in crafting products in various specifications, we cater to bespoke customer needs. Every order is subject to a thorough inspection throughout the manufacturing process, ensuring it aligns with your expectations.

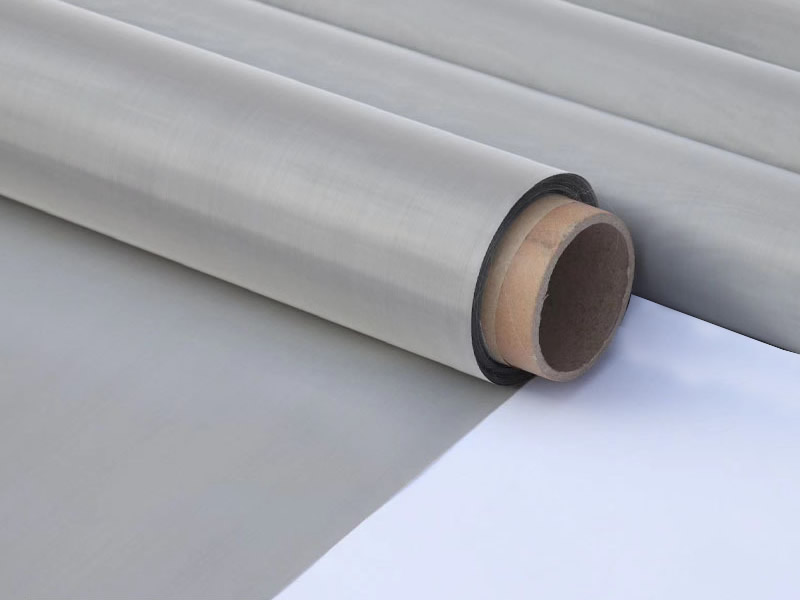

Stainless Steel Wire Mesh

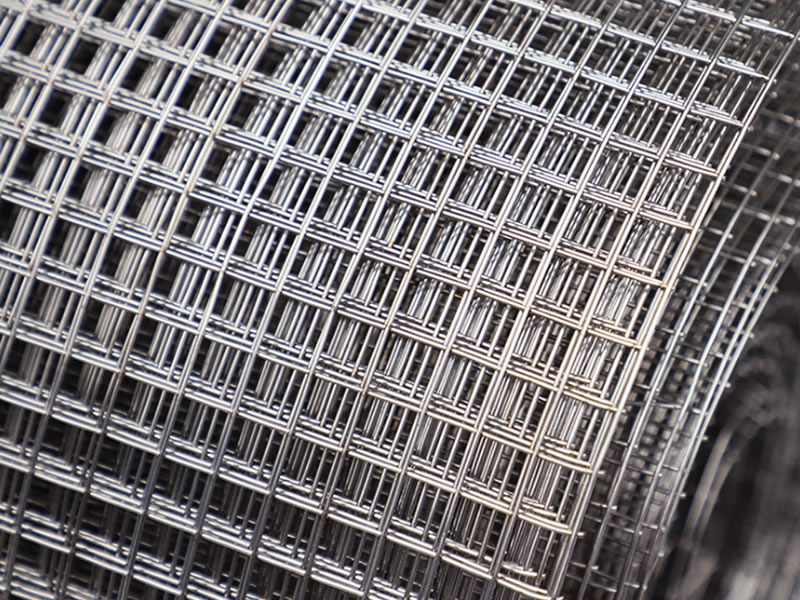

Stainless Steel Welded Mesh

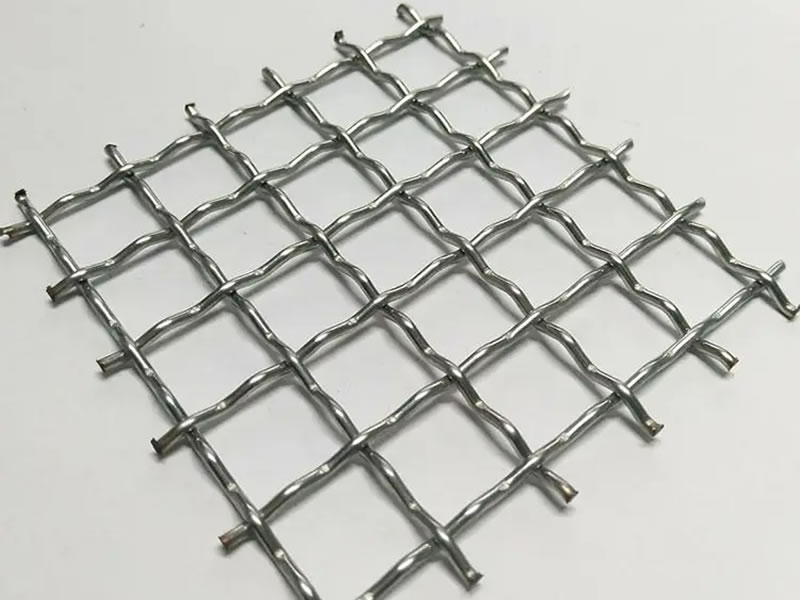

Crimped Wire Mesh

Hexagonal Wire Netting

Wire Conveyor Belts

Filter Elements

Stainless Steel Wire Rope

Barbed Wire

Stainless Steel Wire

Razor Wire