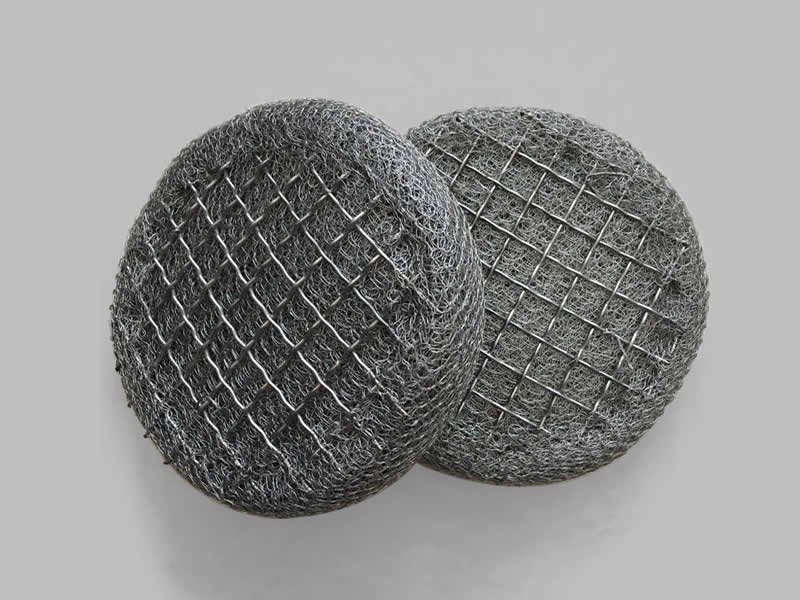

Demister pads, designed to extract liquid droplets from gas streams, play a crucial role in preserving the efficiency of gas-liquid processes. These pads prevent product loss and shield equipment from harm, making them essential in petrochemicals, oil and gas, and environmental sectors. They enhance operational efficiency and ensure compliance with environmental norms, highlighting their importance in maintaining gas purity and prolonging equipment life.

Chosen for their exceptional corrosion and rust resistance, stainless steel demister pads offer unparalleled chemical stability, effective separation, and high temperature resilience, making them the preferred option in various industrial settings.

Demister Pads

Materials of Stainless Steel Demister Pads

- SS 304: Known for its excellent corrosion resistance and durability, SS 304 is a common choice for applications with less exposure to harsh chemicals or extreme temperatures.

- SS 316: Offers enhanced corrosion resistance compared to SS 304, making it suitable for use in more aggressive environments, such as those with higher chloride levels or acidic conditions.

- SS 316L: Similar to SS 316 but with lower carbon content, SS 316L provides even better corrosion resistance, especially in welded sections, ideal for very stringent applications.

- SS 904L: Highly resistant to corrosion, especially in sulfuric, phosphoric, and acetic acids, SS 904L is used in extremely corrosive environments, ensuring longevity and reliability.

- Duplex Stainless Steel: Combines the benefits of austenitic and ferritic stainless steel, offering high strength and excellent resistance to corrosion and stress corrosion cracking, suitable for challenging industrial applications.

- These materials are selected based on the specific requirements of the operation, including resistance to corrosion, temperature endurance, and mechanical strength, ensuring optimal performance of the demister pads in various industrial settings.

Situated in Anping County, the nucleus of the wire mesh industry, our company stands as a testament to the seamless integration of traditional craftsmanship and contemporary innovation. As both a manufacturer and exporter, we offer a wide array of wire mesh products with diverse specifications and incorporate advanced technological solutions, serving the global market. Our portfolio exemplifies outstanding quality across a broad spectrum of wire mesh products. We are committed to providing optimal solutions for various applications, including industry, decoration, and filtration, among others. Our journey is marked by a steadfast dedication to research and development, ensuring the continuous introduction of versatile product lines designed to meet the complex needs of our clients worldwide.

Our approach to manufacturing combines advanced technology with refined techniques, ensuring each product is crafted to meet the highest industry standards.